Negative pressure Leak Tester commercial|leakage testing : exporters The Positive and Negative Duct Accreditation (PANDA) System Model . WEBSockShare remains a popular streaming site, attracting millions of users every day. The site continues expanding its library, adding new movies and TV shows. Despite legal challenges, the platform remains committed to .

{plog:ftitle_list}

Studio25 nace en 2015 y a día de hoy son ya 5 centros y ofici.

Ductwork Leakage Testers. The TSI Positive and Negative Duct Accreditation (PANDA) System, PAN200 Series, is designed to provide fast, accurate duct leakage detection, as well as duct .The Positive and Negative Duct Accreditation (PANDA) System Model .Our Duct Air Leakage Tester (DALT 6900), delivers the most accurate test results in either POSITIVE or NEGATIVE setting while delivering ±10 inches of water gauge pressure in the .

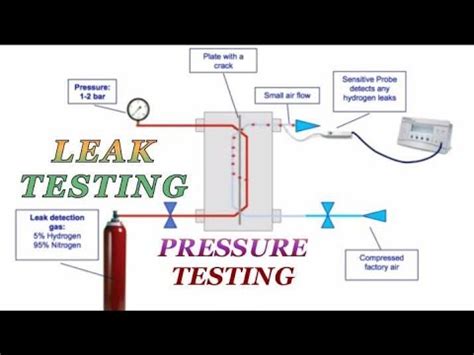

For negative pressure testing (5b), the fan intake will be connected. With McGill AirFlow’s 4-inch Leak Detective test components, the fan comes equipped with a tapered nozzle, which can . The test is performed once in a positive pressure mode and once in a negative pressure mode, and the results are then averaged; this increases the accuracy of the test if the bias pressure is above zero. . It is advisable to . Pressure testing relies on established guidelines and specifications to ensure the safe and precise examination of pressure systems. Several essential standards are commonly employed for pressure testing, .If the casing or liner top packer does not have the required integrity, there may be an additional leak path that could jeopardize the production process and even pose danger to the safety of the well. A negative pressure test, also known as the inflow test, is conducted to test the integrity of a well. While carrying out an inflow test, the .

What is a Vacuum Decay Leak Test? Vacuum Decay leak testing is used on a variety of products that can only be leak tested at negative pressure. The Optima vT can be used to leak test products, typically less than one liter at a fairly low vacuum, < 0.25 atm. Testing products greater than one liter can be achieved with high flow valves.This leak testing method capitalizes on the fact that a leak will allow a quantity of gas – remaining uniform through a period of time – to enter a sufficiently evacuated device (impeded gas flow, see Fig. 1.1). . the test gas which has passed through leaks and into the apparatus. Another option is to use the positive-pressure leak test .Per ANSI/ASHRAE Standard 90.1-2010, “positive pressure leakage testing is acceptable for negative pressure ductwork”. Even so, you will see specifications that may require return air or exhaust systems to be leak tested under a vacuum (negative pressure). To perform a proper duct leakage test under negative pressure using an ORIFLOW duct leakage tester, perform .Leak Testing 101: A Primer 4 Vacuum Decay Leak Testing Similar to pressure decay leak testing, vacuum decay leak testing evacuates air from the part or system under test to detect leaks. Vacuum decay leak testing is commonly used with parts that could have leaks from external sources, such as underwater sensors, pipes, or outdoor electrical .

Pressure Testing: Connect one end of the orifice tube to the duct system using a short piece of single-wall flexible duct. The arrow on the calibration sticker shows direction of flow. Step 4b — Typical Negative Pressure Testing: For all standard components except the 4-inch, two options exist for performing negative pressure testing. 1.Vacuum and Pressure decay leak testing Basel, 27. February 2020 Presenter: Patrick Schlatter, WILCO AG, CH Head of Sales Europe / Key Account Manager. 2 Overview . ☺most similar to negative samples (used for method development) Determining the measuring capability of a machine: needle valve ☺adjustable orifice

Vacuum and Pressure decay leak testing Venice, 22. March 2019 Presenter: Dr. Matthias Kahl, Head of R&D WILCO AG, CH . –LFC, P, V (different types) –pressure curve / course –steps of the differential pressure test • Method selection • Equipment in process control • Applications of differential pressure . most similar to negative . HVAC duct leakage testing is a critical maintenance task that ensures system efficiency, reduces energy costs, and prolongs the lifespan of your HVAC unit. This post outlines the importance of duct leakage testing and describes the tools, such as duct blasters, manometers, and smoke machines, needed to detect and locate leaks. It provides a step-by .Fieldpiece SDMN6 - SDMN6, Dual-Port Manometer & Pressure Switch Tester- Overview: The SDMN6 dual-port manometer measures gas and static pressure and also accurately tests pressure switches by simulating a draft with an internal pump. A pressure switch is a safety device that prevents the furnace from running in an unsafe manner.

Negative pressure testing, also know as inflow testing, offers oil and gas companies a reliable way to test well barrier integrity.These tests are so critical that regulators have stepped in to require them via the Code of Federal Regulations (CFR) Title 30 § 250.721(g).During a negative pressure test, displacement occurs through the use of a lower . The pressure increase leak test method can be a good alternative to trace gas methods, given the ability to test parts at very high pressures (up to 1,000 bar), with very short cycle times. . This measuring chamber is not directly pressurized with positive or negative pressure but is dosed via a previously evacuated or filled pre-volume. The . This article explores the negative pressure test in drilling, explaining its importance as a safety protocol and detailing the steps involved. . Any drop in pressure indicates a potential leak or defect in the system. .

Air leak testing is a common method used for leak testing. It is a flexible test method that can be used to leak test a wide variety of parts and applications. Under the umbrella of air leak testing are several specific methods. In this ebook, we’ll cover the following types of air leak testing: > Pressure Change Method A

Commercial testing utilizes a five to 10 horsepower fan to perform leakage testing, and in order to be effective up to 7-in. of pressure is required. This fan capacity is 70 times the pressure than residential duct testing utilizes today. The higher pressure is essential to adequately pressurize a duct system to achieve accurate results. Understanding the negative pressure test on a drilling rig is crucial for maintaining control and ensuring safety. This article explains the importance of this test and provides a step-by-step procedure for conducting it effectively. . If the pressure drops, it may indicate a leak in the chamber or a malfunctioning component that needs .

When it comes to vacuum testing, this presents an issue. Vacuum testing, according to ASTM C1244-05, “Standard Test Method for Concrete Sewer Manholes by the Negative Air Pressure (Vacuum) Test Prior to Backfill,” is a great way to measure watertightness; however, as the standard title states, it should only be performed prior to backfill.

Any change in the pressure differential between inside and outside air will in some way affect the operation of a system, most commonly that affect is a negative one. A test and balance, as well as the simple performance test in International Mechanical Code section 507.16.1 should be included in all jobs, as code inspectors are increasingly . Leak testing is a broad term that includes a multitude of technologies. For the purposes of this article, different leak test methods will be referenced but not described in full detail. This article defines the broad term leak test and takes a closer look at the pressure decay leak test method. Furthermore, this article will describe how a pressure decay test works, .7.4 Negative Leak Rate. Open the control valve on the Negative Flow Metering device until the pressure stabilizes at the negative leak rate pressure described in CP-201 section. Maintain steady state pressure by using the control valve for at least ten (10) seconds. Steady state flow is indicated by a pressure change of no more than 0.05 inches H

o'brien compression test

Learn proper anesthesia machine operation, maintenance, and troubleshooting in this how-to video focused on performing a low-pressure system leak test. If the anesthesia machine contains a check valve at the common gas outlet, then a negative-pressure leak test should be performed in conjunction with a positive-pressure leak test (see below). A positive-pressure leak test will not detect a leak of the low-pressure components that are upstream from the check valve. Fun Fact: The negative .In the event of a leak in the test item, negative pressure outside the test item causes airflow out of the isolator system. . Manufacturer’s catalog cuts and instruction sheets for all commercial components. Electrical, mechanical, P&ID’s and assembly .

Pressure decay is one of the most widely used methods of leak testing in manufacturing and is ideal for a sealed component with an access port. In this test, a product is attached to a leak tester and filled with air. Once pressurized, the air source is valved off and the pressure is allowed to settle. Rob Siegel. In my book Just Needs a Recharge: The Hack Mechanic™ Guide to Vintage Air Conditioning, I make the case that those “A/C recharge .95” signs you see at service stations are perilously close to fraud. If a system needs to be recharged, it’s because the refrigerant has leaked out, so the leak first needs to be found, then needs to be fixed.

system pressure testing for leaks

no duct leak testing

5 dias atrás · 25/02/2024 04h02 Atualizado há 4 dias. Inter e Grêmio entram em campo neste domingo, às 18h, no Estádio Beira-Rio, em Porto Alegre. O clássico Gre-Nal 441 é .

Negative pressure Leak Tester commercial|leakage testing